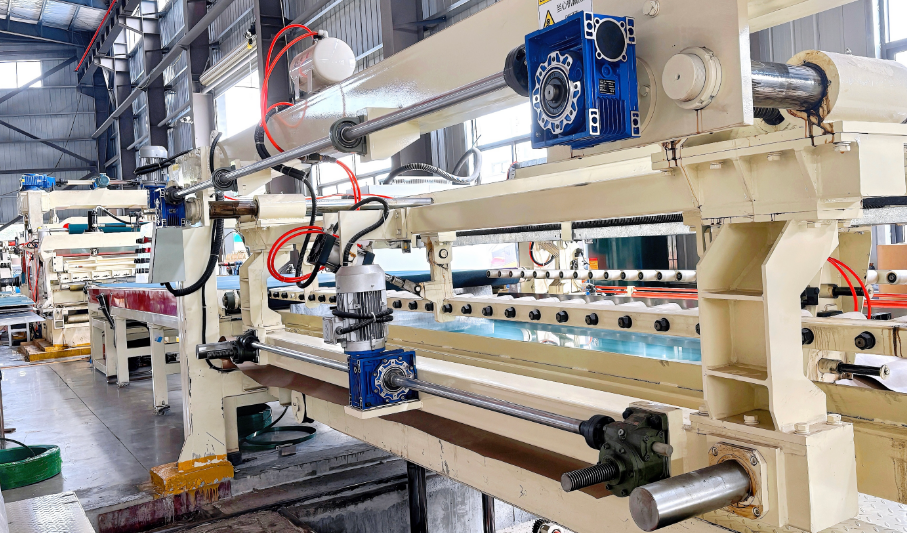

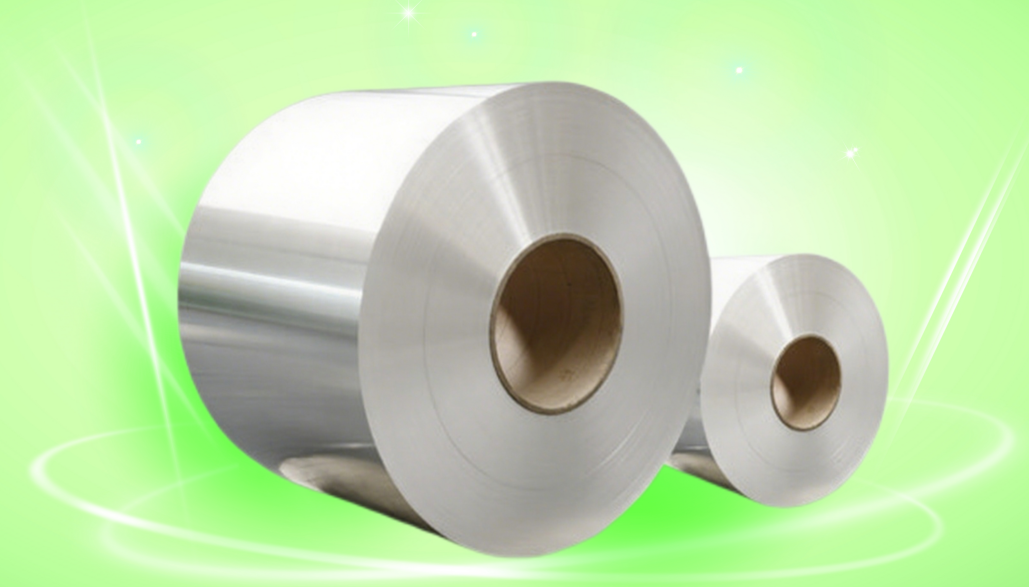

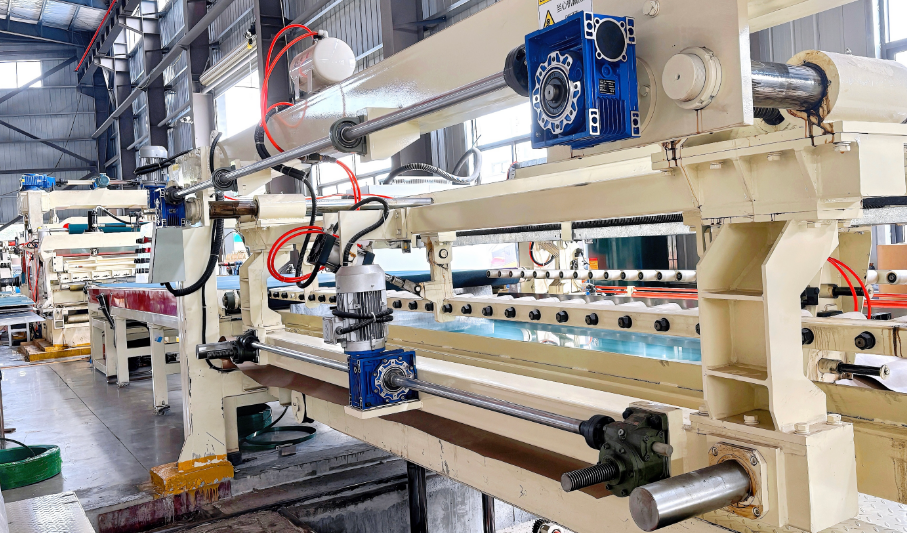

Guangxi Aide Metal Products Co., Ltd., founded in 2017, adheres to the core values of "responsibility, responsibility, enterprising and tolerance", focuses on the research and development, production, and processing of high-precision, high-performance aluminum alloy plates and strips, and is a new force in the field of aluminum metal material processing. As a leading provider of aluminum solutions, its products are used in aerospace, rail transit, shipbuilding, automotive lightweight, new energy batteries, 3C electronics, architectural decoration, machinery and packaging containers and other fields. The market covers Europe, North America, Oceania and Southeast Asia.